Description

When city developers began the process of planning for Music City Center in downtown Nashville, they quickly realized that a downtown electrical substation was going to be in the way. Fortunately for Nashville Electric Service (NES) this substation was 70 years old and due to be updated.

NES found that they could relocate the facility to another property in the nearby North Gulch neighborhood. This provided them the opportunity to update and improve the entire downtown secondary network to be more energy efficient and reliable.

Integrating a large and typically undesirable piece of infrastructure into the downtown fabric can be a challenge. NES looked to Moody Nolan to create a clever way to minimize the visual clutter that makes up a typical power substation and shield the various elements from public view.

By enclosing and shielding the equipment, Moody Nolan‘s team found a creative way to integrate the structure. This generated many opportunities to create visual interest in what would normally be a more nondescript structure.

SSM brought our own expertise into play by fabricating and installing the key components needed to clad the substation.

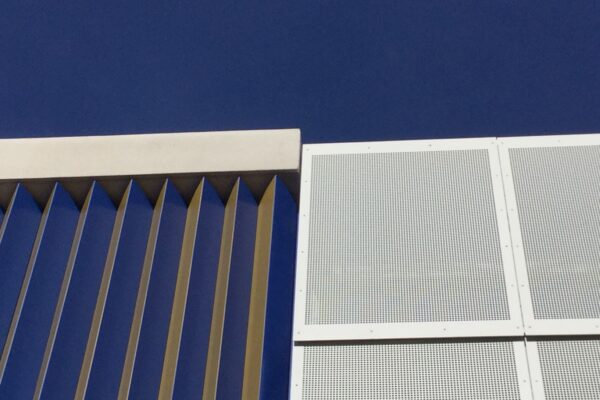

One of the most striking features are the vertical fins that clad part of the south elevation. Fabricated from 1/8″ thick aluminum, the material is folded back to have a 60 degree interior angle. This creates a “V” shaped fin with two faces. Painted in the two NES identity colors, one surface of the fin is painted “sorcerer” blue and the other face is “autumn” gold. As one views the fins from different angles, the visual appearance changes as the two colors become more or less visible.

The majority of the structure is clad with perforated panels of various sizes and perforation patterns. In fact, there are 11 different perforation patterns – ranging from 10% open to 45% open – used to create different degrees of transparency, graphic elements and text. Patterns were perforated by SSM onto 3/16″ thick aluminum plates, cut to different sizes based upon their location. Panel widths varied too, from 1′ to 5′ wide and are arranged with an overlapping pattern to create depth and shadow lines.

SSM also designed, engineered, fabricated and installed the embeds, support structures, Zee purlins and other framing system components to support the cladding components.